What’s Inside

ToggleThe journey from laboratory bench to patient bedside is a delicate balancing act. Every pill, vial, and medicine bottle must meet stringent standards, not just for efficacy, but to ensure stability at every step. This is where the meticulous process of stability testing becomes essential.

What is Stability Testing?

Stability testing is an intrinsic part of drug development and manufacture, in which samples of drugs are tested vigorously to determine how the quality would change with environmental conditions exposed over time. This procedure proves that medications are safe and effective throughout their shelf life.

Benefits of Stability Testing Integration

LIMS empowers pharmaceutical companies to enhance their testing protocols by automating data management and streamlining processes. Integration of Laboratory Information Management System (LIMS) into stability testing workflows can make a transformative difference. This integration not only enhances accuracy but also empowers companies to maintain product integrity while accelerating time-to-market.

- Centralized data management: All stability protocols, batches, and testing data are stored in one secure, digital repository accessible in real time.

- End-to-end traceability: Track every sample, condition, and test result from initiation to completion with detailed audit trails.

- Automated scheduling and reminders: The system automatically triggers alerts for due tests, reducing manual tracking errors.

- Improved compliance: Aligns with regulatory standards like ICH Q1A, 21 CFR Part 11, and EU Annex 11 by ensuring validated workflows and data integrity.

- Seamless instrument integration: Stability chambers and analytical instruments can be interfaced with LIMS for real-time data capture.

- Faster review and reporting: Generate stability summaries, trend reports, and Certificates of Analysis (COAs) with a single click.

- Enhanced decision-making: Enables trend analysis across multiple batches or products, helping detect early stability issues.

- Reduced manual effort: Eliminates paper-based tracking and repetitive data entry, freeing scientists to focus on analysis rather than administration.

- Multi-site visibility: View ongoing studies across multiple facilities or climatic zones from a centralized dashboard.

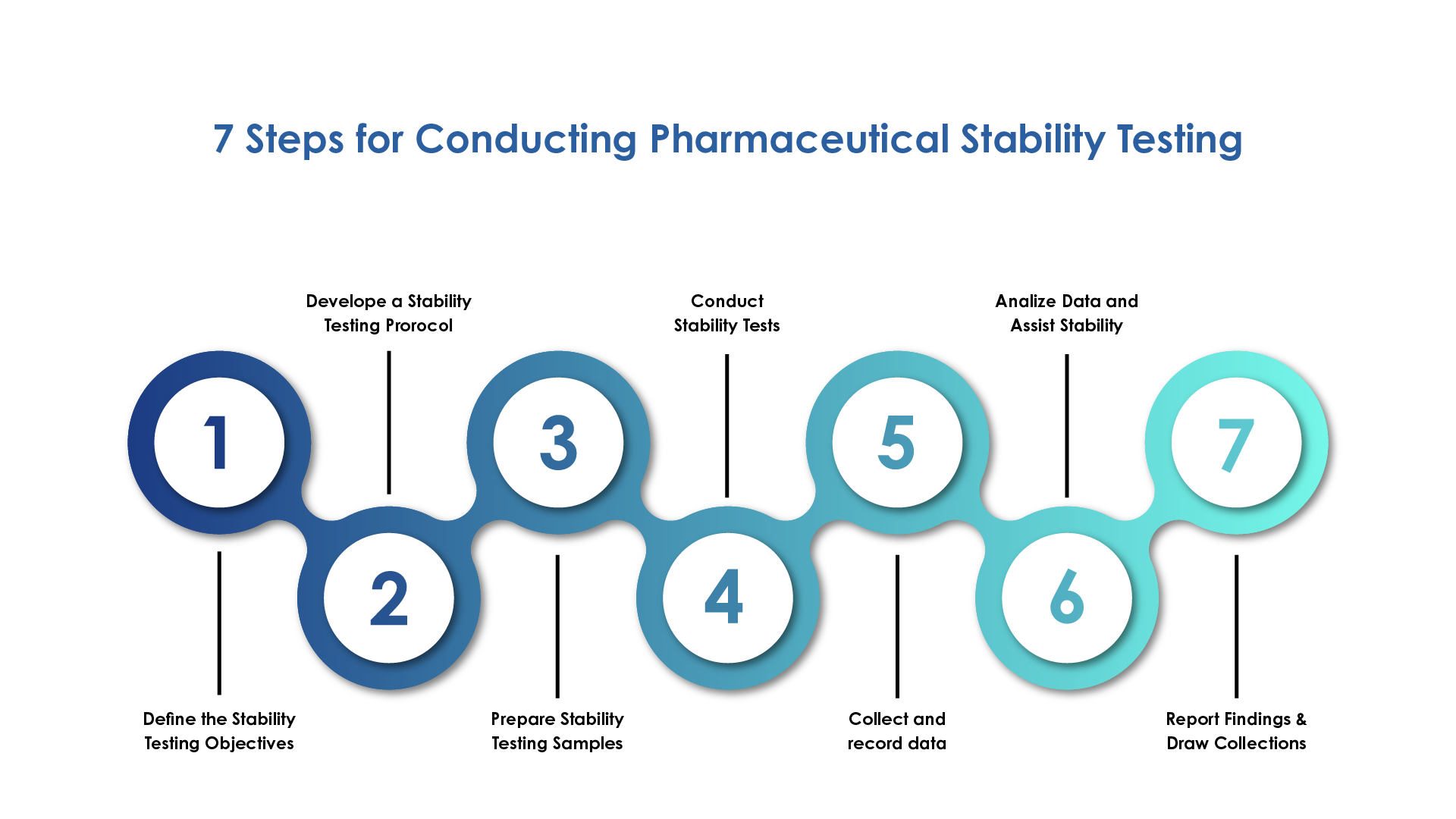

How is Stability Testing Typically Conducted?

Stability testing is a methodological test and performed through controlled conditions such as temperature, humidity, and light, in which samples are subjected to inspection at given periods.

Key parameters monitored in this process include physical properties (appearance, texture), chemical integrity (active ingredient levels, pH), and microbiological stability.

- Long-term studies: Conducted over a minimum of 12 months at 25°C/60% RH

- Accelerated studies: Lasting 6 months at 40°C/75% RH

- Intermediate studies also last 6 months, conducted at 30°C/65% RH

Types of Stability Studies

Pharmaceutical companies conduct various stability studies to assess product quality over time. Common types include:

- Real-time/room temperature studies

- Accelerated stability testing

- Intermediate studies

- Freeze/thaw cycles

- Photostability testing

- Bulk hold studies

These studies are essential to identify conditions for optimal storage, shelf life, and possible degradation mechanisms to guarantee the safety and efficacy of pharmaceutical products throughout the product’s life cycle.

The Role of LIMS in Stability Testing

A laboratory information management system (LIMS) plays an integral role in managing the vast amounts of data generated during stability testing. LIMS allows analysts to:

- Design stability test protocols and sample plans

- Track samples through the testing process

- Automate calculations and report generation

- Compare test results to established specifications

- Flag out-of-specification or failing results

Why is Integrating LIMS for Pharmaceutical Stability Testing Important?

- Managing Stability data

Managing the vast amounts of data generated during stability studies can be a daunting task. Laboratory Information Management Systems (LIMS) play a crucial role; they can electronically capture, store, and report data from instruments used in testing. This includes:

- HPLC systems for analyzing potency and degradation products

- Dissolution testing apparatuses

- Spectrophotometers and pH meters

By managing this stability data and testing workflow in an electronic, centralized system, LIMS enables scientists to identify potential issues sooner.

- Defining storage locations

LIMS allows users to define and manage detailed storage locations- such as rack, shelf, and position ensuring precise organization and tracking of stability samples. Further, it allows taking action to resolve stability concerns and ensure the product meets its approved shelf life.

- Automating tasks

LIMS streamlines and automates common tasks like report generation and sample registration. LIMS-managed stability data provides the transparency, traceability, and reproducibility needed to satisfy stringent regulatory requirements.

- Streamlining Stability Management

Integrating LIMS into pharmaceutical stability testing can significantly enhance efficiency and compliance. By automating sample generation, storage control, and data collection, a LIMS reduces human error and ensures data integrity. This integration allows for consistent handling of samples and simplifies complex processes related to protocol adherence.

- Advanced Capabilities for Informed Decision-Making

Modern LIMS solutions offer advanced reporting features, providing valuable insights through shelf-life prediction models and trend analysis tools. These capabilities enable better decision-making in drug development and quality control.

A Well-implemented LIMS can adapt quickly to evolving regulations, supporting new methodologies while ensuring compliance with guidelines such as ICH Q1A(R2).

- Optimizing Workflows and Resources

LIMS integration optimizes resource allocation and improves response times in stability testing. By automating workflows and integrating with testing instruments, LIMS streamlines the entire stability testing process, from protocol creation to final reporting.

How to Find the Right LIMS for Your Stability Testing Needs?

An ideal LIMS should not only meet the specific needs of pharmaceutical stability testing, but it should also enhance the overall efficiency, compliance, and quality of your laboratory operations. So, when selecting a LIMS for pharmaceutical stability testing, it is critical to consider a few key factors.

- Scalability and Performance

LIMS that can handle your expected volume of concurrent users and requests without performance issues will be an ideal choice. LIMS & ELN platforms can also be customized in a scalable solution designed to support complex stability testing workflows.

- Customization and Flexibility

Most LIMS come with configurable stability testing templates and workflows. A no-code workflow engine allows for easy customization of batch assessments and sample traceability, adapting to your specific protocols.

- Data Integration and Analysis

Choose a LIMS that integrates data from various testing instruments and provides user-friendly analysis tools. It should offer a single interface for data integration and science-aware analysis, eliminating the need for SQL expertise.

- Compliance and Reporting

As regulatory scrutiny intensifies and stability data volumes grow, LIMS will become an indispensable tool for maintaining a competitive edge.

The right LIMS solution empowers your team to make data-driven decisions, transforming your stability testing processes to position your organization at the forefront of pharmaceutical excellence.

CaliberLIMS’s Robust Stability Module

CaliberLIMS offers a robust stability module specifically engineered to accelerate pharmaceutical stability testing while ensuring compliance with the highest standards

This powerful tool ensures data integrity, aligning with stringent regulatory requirements. Its intuitive interface allows users to effortlessly define and configure stability protocols for various materials, including temperature and humidity parameters.

The advantages of implementing CaliberLIMS extend far beyond data management. Successful integration into pharmaceutical workflows not only enhances compliance but also streamlines operations and provides invaluable insights that can drive innovation.

Embrace the future of pharmaceutical stability testing with CaliberLIMS and experience the profound impact it can have on your operations.